A Guide for Architectural Design

Clash Detection in Modern Design: Why It Matters for MEP and Structural Systems

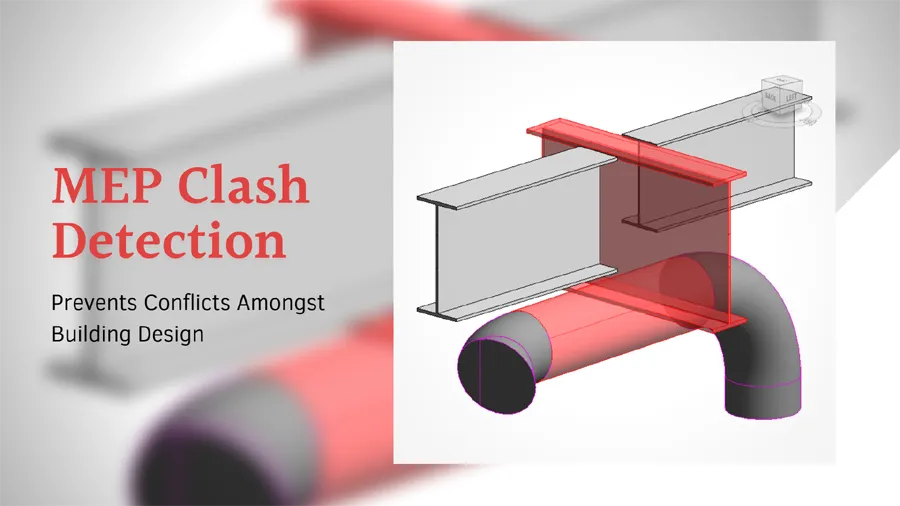

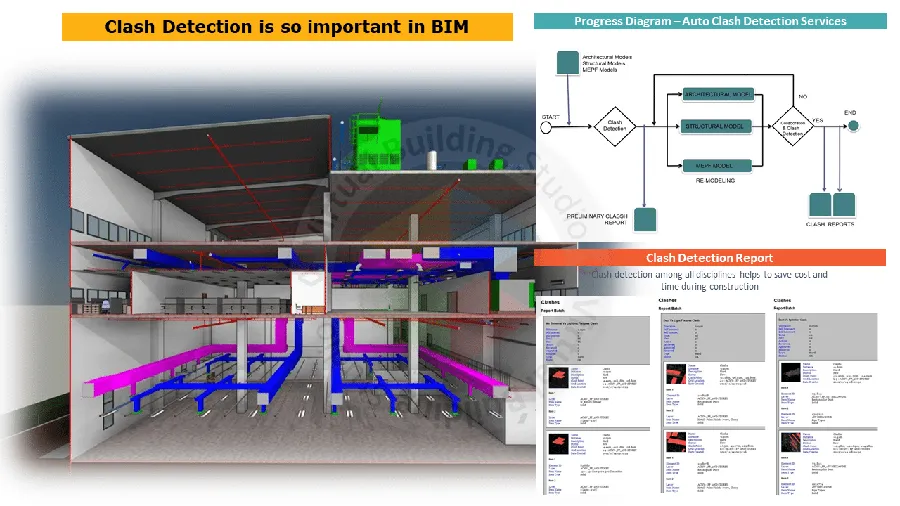

Clash detection is the process of finding and resolving conflicts between mechanical, electrical, plumbing (MEP), and structural systems before construction begins. For architects and builders in Roanoke VA and southwest Virginia, using clash detection in BIM (Building Information Modeling) keeps projects on schedule, reduces costly errors, and ensures that every duct, pipe, and beam fits exactly where it should—long before anyone steps on site.

What exactly is clash detection?

Clash detection is one of the biggest advantages of modern BIM workflows. It’s a digital quality-control step that compares the different 3D models produced by architects, engineers, and builders to identify points of conflict.

In traditional AutoCAD drafting, each discipline might draw its systems separately—architectural floor plans, mechanical layouts, electrical schematics, and so on. During construction, it’s common to discover that a duct runs through a structural beam, or that a sprinkler line crosses a light fixture. Fixing those problems on-site leads to delays, change orders, and wasted materials.

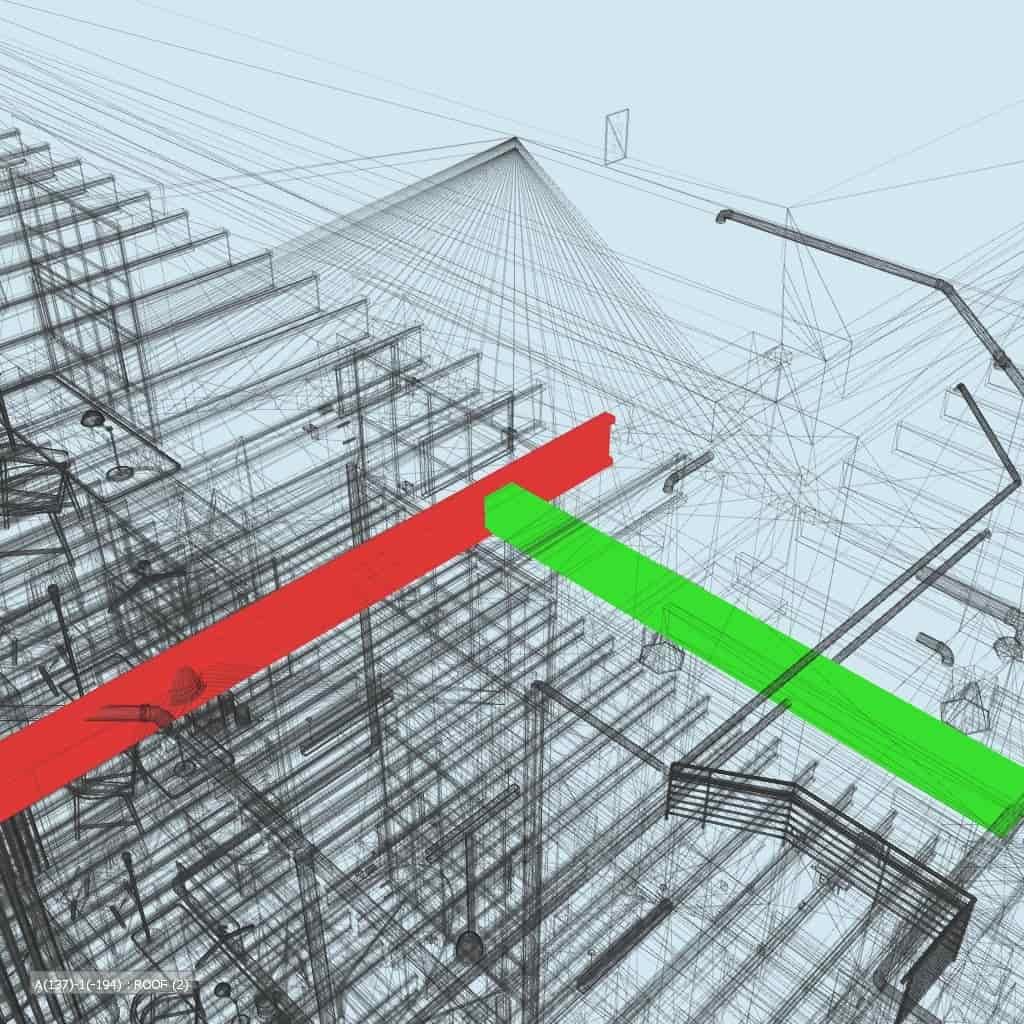

With clash detection, these issues can be spotted virtually before they ever happen. Using tools like Autodesk Revit, Navisworks, or BIM 360 Model Coordination, design teams merge their models into a single, coordinated 3D environment. The software automatically analyzes intersections and clearances, highlighting problem areas that need design adjustments.

This process is becoming standard in larger projects around Roanoke, Lynchburg, and Blacksburg—especially at institutions like Virginia Tech, Carilion Clinic, and regional school systems where mechanical and electrical complexity is high.

Why clash detection matters for MEP and structural systems

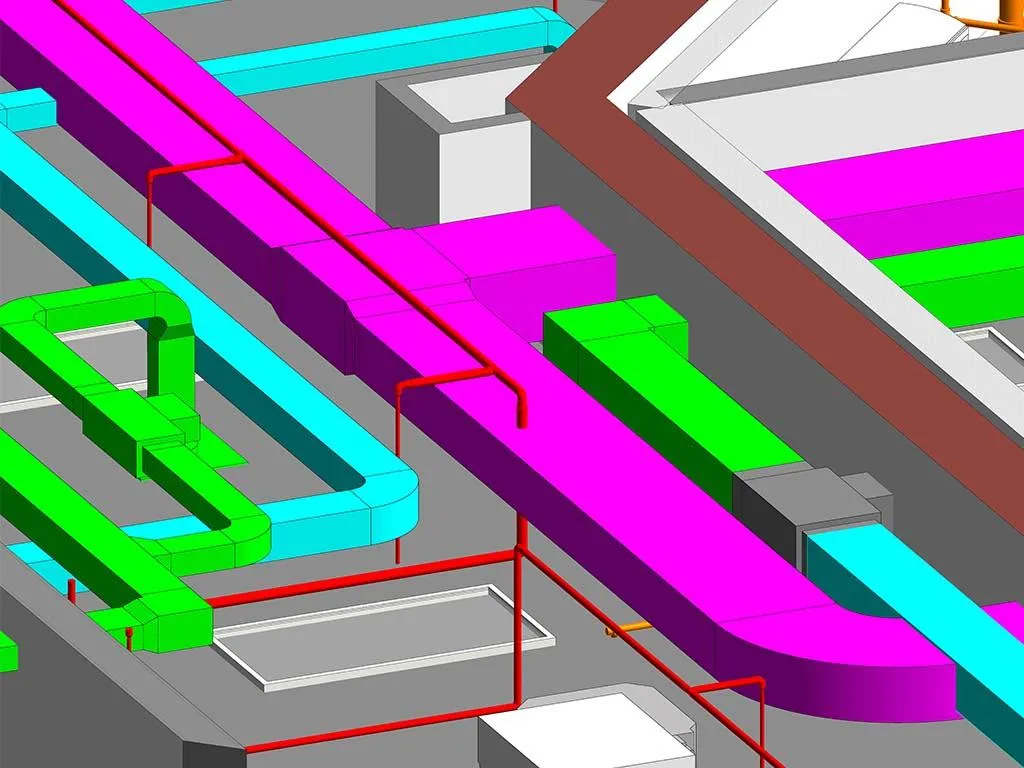

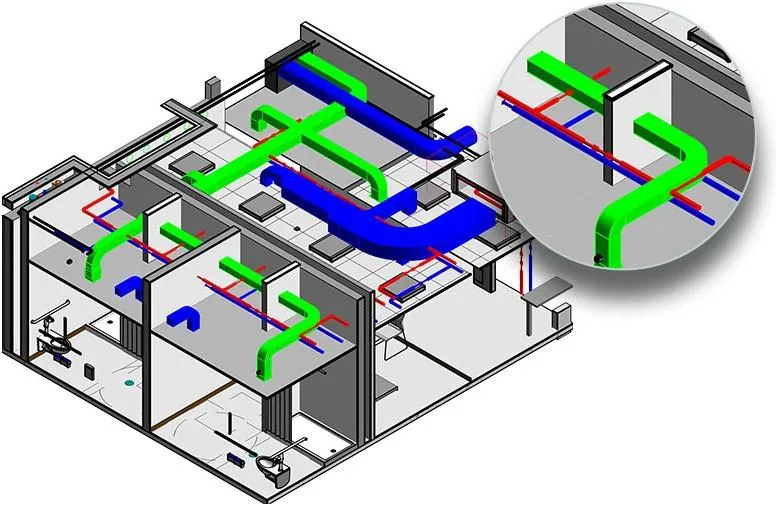

The most common clashes happen between MEP and structural components. MEP systems—like ducts, pipes, conduits, and cable trays—often snake through tight ceiling spaces and floor slabs where structure and architecture compete for room. Without coordination, there’s a high chance that a steel beam will intersect a duct route or that a plumbing stack will cut through a concrete beam.

In projects across the Blue Ridge region, these mistakes are magnified because many buildings are built on slopes or within existing structures, leaving little margin for error. A clash in the model could represent a serious problem in real life—one that might require cutting into structural framing or rerouting utilities at great expense.

By identifying those issues digitally, clash detection allows architects, engineers, and contractors to resolve conflicts early in design. This means fewer field changes, safer structures, and more predictable construction costs.

The main types of clashes found in BIM models

Clashes fall into three main categories:

Hard clashes happen when two physical elements occupy the same space, such as a steel beam colliding with a duct or conduit.

Soft clashes involve clearance problems—when there isn’t enough room between elements to meet code or maintenance requirements.

Workflow or time-based clashes occur when the order of construction tasks creates conflicts, such as installing ductwork before a beam is placed.

Understanding the difference helps project teams prioritize. Hard clashes are urgent, while soft or workflow clashes can often be resolved through design tweaks or schedule adjustments.

How clash detection works step by step

Combining models

Each design discipline—architectural, structural, mechanical, electrical, and plumbing—creates its own 3D model. In BIM software, these are combined into one federated model that represents the entire building.

Setting parameters

The project manager defines what to check: for example, ducts against beams, pipes against walls, or conduits against ceiling structures. The software also uses tolerance values, such as a minimum one-inch clearance between systems.

Running clash tests

The software scans for intersections and produces a list of issues with coordinates and visual markers. It can show 3D images of where conflicts occur, making them easy to understand even for non-technical team members.

Assigning and resolving

Each clash is assigned to a responsible party. The mechanical engineer may need to reroute a duct, or the architect may adjust a ceiling height. After changes are made, a new test confirms the clash is resolved.

Iteration and review

This process repeats several times throughout design development and construction documentation. By the time drawings are issued for construction, the model should be nearly “clash-free.”

Local benefits for Roanoke and southwest Virginia projects

In the Roanoke Valley, clash detection is more than just a technology buzzword—it’s a practical safeguard against costly mistakes.

For healthcare expansions, such as those at Carilion Clinic or LewisGale, space is tight and systems are dense. Every square foot of ceiling and wall cavity is filled with mechanical and electrical runs. Clash detection helps ensure all systems fit without affecting patient areas or critical equipment.

In education and research facilities, such as those near Virginia Tech, BIM coordination ensures labs, classrooms, and utilities line up perfectly. It’s particularly valuable when combining new construction with older structures, which often have irregular framing or limited access.

Even commercial renovations in downtown Roanoke or Salem benefit from basic clash detection. Older buildings weren’t designed with modern HVAC systems in mind. Modeling existing conditions and checking new systems against them helps prevent surprises during demolition and installation.

Best practices for successful clash detection

Start early.

The earlier clash detection begins, the more flexibility designers have to make changes without major cost impact. Waiting until construction documents are nearly complete defeats the purpose.

Use consistent modeling standards.

When every consultant uses the same coordinate systems, naming conventions, and file origins, model coordination runs smoother. This reduces “false positives” that occur when models aren’t aligned properly.

Meet regularly for review.

Holding coordination meetings—either in person or virtually—ensures that issues are discussed and resolved quickly. This is especially helpful for firms collaborating across southwest Virginia, where some partners may be in Lynchburg, Blacksburg, or further east in Charlottesville.

Keep realistic tolerances.

Not every proximity is a true clash. Set clearance rules that reflect real-world conditions and code requirements.

Combine clash detection with visual review.

While automated checks catch most issues, visual walkthroughs in the 3D model can reveal aesthetic or constructibility problems that algorithms miss.

Challenges and limitations

Even with powerful software, clash detection isn’t foolproof. Low-detail models can produce false alarms, and overly strict rules can overwhelm teams with hundreds of minor issues. Inexperienced users may fix a clash in one area only to create a new one elsewhere.

For smaller firms, software costs and training are real considerations. However, cloud-based coordination tools like Autodesk Construction Cloud and Revizto make it more accessible. TAS Design Inc. often recommends a phased approach—starting with partial coordination (mechanical vs. structure) and expanding as project complexity grows.

As more Roanoke-area contractors and design teams adopt BIM, clash detection will become standard practice. Virginia’s Department of General Services and major institutions are already moving toward BIM-based project delivery.

Within the next few years, even mid-sized commercial builders and residential developers will expect basic coordination checks before breaking ground. For local architects, embracing this process now ensures smoother collaboration, better design documentation, and stronger relationships with engineers and builders.

Roanoke Clash Detection System FAQs

Q: What software does TAS Design Inc. use for clash detection?

A: Our team typically uses Revit and Navisworks for model coordination, along with Autodesk Construction Cloud for issue tracking and document sharing.

Q: Can clash detection help in residential design?

A: Absolutely. While homes don’t have the same level of complexity as hospitals or schools, clash detection still helps ensure HVAC and plumbing fit within tight framing spaces, especially in renovations.

Q: How early should clash detection begin?

A: Ideally during design development, once basic systems are modeled. Running early tests allows for efficient routing before the design is finalized.

Q: Does clash detection replace field inspections?

A: No, it complements them. Even with thorough coordination, field verification is essential to ensure that installation matches design intent.

More Articles From TAS Design

Contact Us

Office Hours

Social Media

Mon- Fri 8 am - 5 pm

Sat, Sun- Closed except by appointment

Contact Us

1 540-302-2593

2507 Bluff Road

Roanoke VA 24014

Office Hours

Mon- Fri 8 am - 5 pm

Sat, Sun- Closed except by appointment